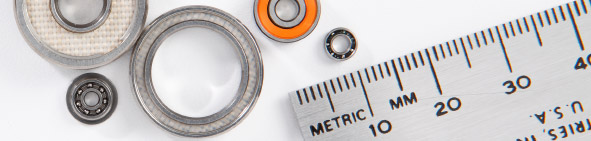

Shield & Seal Types

Shields and seals are protective closures which retain lubricants and assist in preventing contaminants from reaching internal surfaces. In torque-sensitive applications, it may be advantageous to use shields rather than seals because there are no contacting surfaces to create drag.

The following chart illustrates the more common type of shields and seals.

Consideration should be given to the compatibility of cage and shield type designs to allow for appropriate clearance. Consult with NPB for availability.

| Description | Type | Design | Material | Operating Temp. Max. |

|---|---|---|---|---|

| Shield - Removable with snap wire. Minimal clearance. Most Popular | Z | Stainless Steel 300 Series |

600F | |

| Seal-Removable with snap wire. Minimal clearance to light contact. Low torque. | L | Glass-reinforced PTFE | 400F | |

| Seal - Excellent sealing characteristics. | D | Buna-N Bonded to Steel Insert | 250F | |

| Seal - Excellent sealing characteristics. High cost. |

D1 | Viton® Bonded to Steel Insert | 400F |

| Characteristic | ABEC 1 | ABEC 3P | ABEC 5P | ABEC 7P | ABEC 9P |

|---|---|---|---|---|---|

| Bore Tolerance Limits | +.0000 | +.0000 | +.0000 | +.0000 | +.0000 |

| –.0003 | –.0002 | –.0002 | –.0002 | –.0001 | |

| Bore 2 pt. out of Roundness | – | – | .0001 | .0001 | .00005 |

| Bore Taper | – | – | .0001 | .0001 | .00005 |

| Radial Runout | .0004 | .0002† | .00015 | .0001 | .00005 |

| Width Variation | – | – | .0002 | .0001 | .00005 |

| Bore Runout with Face | – | – | .0003 | .0001 | .00005 |

| Race Runout with Face | – | – | .0003 | .0001 | .00005 |

* Measument in inches.

† Add .001 to the tolerance if bore is over 10mm (.3937 inch)

Tolerances

Miniature and Instrument Ball Bearings Inner Ring *

The ABEC tolerances listed are current at this catalog’s printing. These tolerances are reviewed regularly and updated as required. The ABMA standards may be obtained by contacting:, 1101 Connecticut Ave. N.W., Suite 700, Washington, DC 20036.